DME Pump

Use

It offers solutions in the following industries:

- Drinking water treatment

- Waste water management

- Cooling water treatment

- Washing systems

- Processing water treatment

- Chemical industry

[/fusion_builder_column_inner]

[/fusion_builder_column_inner]Description – Features

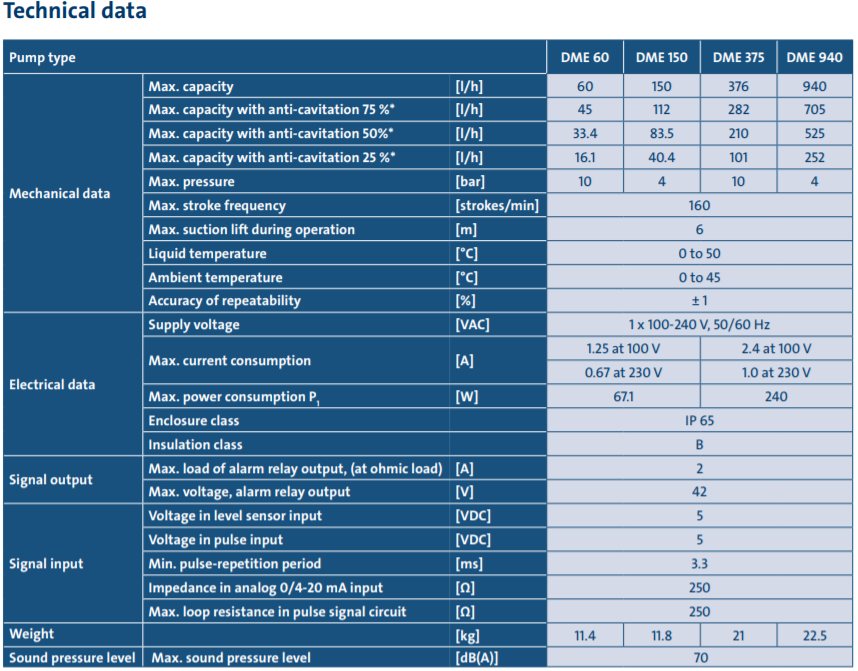

DME dosage pumps set new standards in handling and precision of chemicals. The user can easily install and adjust the pump to precisely discharge the amount of metering fluid required in the motion and flow management process. The pump setting is in ml / h, l / h or gph, and its mode of operation is easily adjusted via icons.

DME pumps are strong and resistant to high pressure.

Features and Benefits

- Accurate and easy setup

- Unique technology

- The small number of variants covers every possible need

- Full pulse control

- Pulse batch control

- Internal clock batch control

- Analogue 0 / 4-20 mA test

- Level control

- Fieldbus Communication Unit

- Head pump – PVDF, polypropylene, 316SS

- Gaskets – FKM, EPDM, PTFE

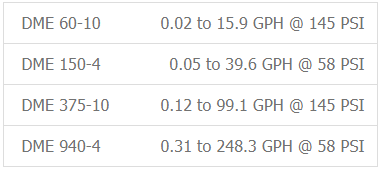

- Performance range: 0,02 έως 248 GPH (έως 940 l / hr)

- Maximum pressure: 145 PSI

- > 1: 800 rotation ratio, +/- 1% repeatability over the entire adjustable range

- > Controlled variable speed motor (1×100-240V, 50 / 60Hz)

- > Backlight display, precise easy adjustment to GPH (l / hr)

- > Simple calibration function

- > Anti-cavitation (slow operation) for viscous liquids

- > Overload protection

- > Optional Flow Verification and Leakage Detection

Control variants:

- DME B – Basic manual control

- DME AR – Automatic control + alarm relay

- DME AP – AR + Profibus

Procedures:

Dosage of biocides and chemicals, lubricant belt for conveyor equipment varying variety of acids, lubricants, coagulation and coagulation factors, cationic and anionic polymers, precipitating agents and disinfectants, CIP applications